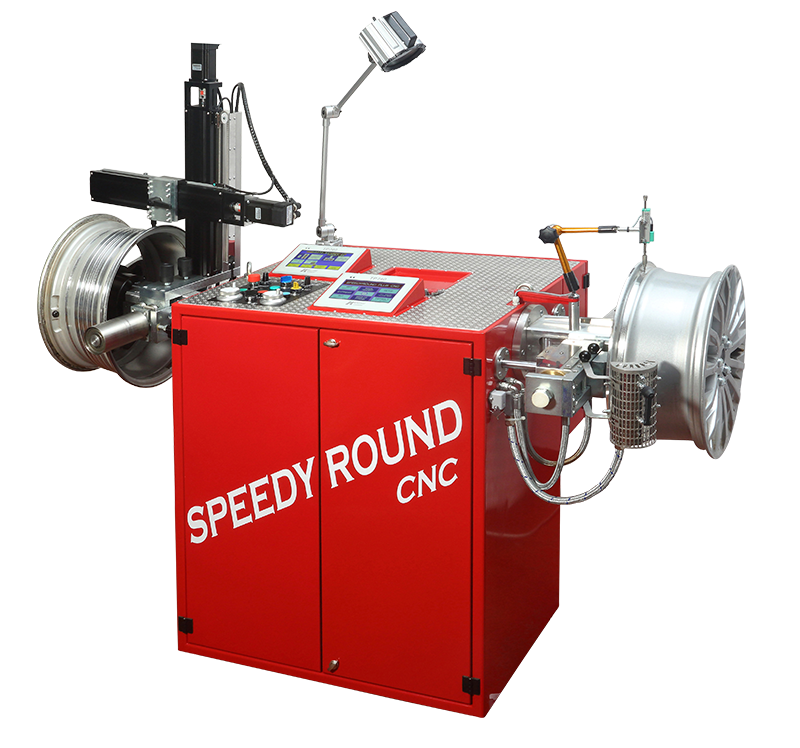

RIM STRAIGHTENER

SPEEDYROUND CNC ®

Automatic alloy wheel straightening and turning machine with two separate PLC for independent function control.

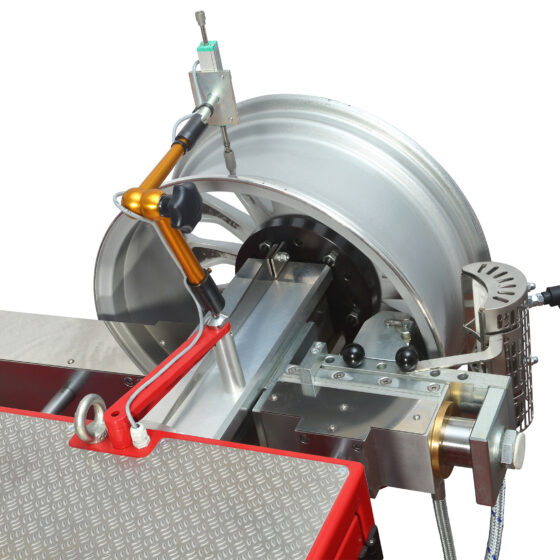

This machine consists of two separate sections: STRAIGHTENING and TURNING. Both processes are completely independent of each other, controlled by two separate PLCs , thus offering the indisputable advantage of optimizing processing times. In the right part of the machine, the one dedicated to STRAIGHTENING, the circle is properly positioned on the flange, measured automatically and then subjected to the various stages of straightening, by means of a rotary tool which acts in pressure on the inner surface of the rim, until the concentricity tolerance OEM is reached! Every step of this process is constantly monitored by accurate, highly sensitive ELECTRONIC sensors, which ensure accurate control of all machining parameters and avoid unpleasant structural problems at the wheel. During the AUTOMATIC straightening cycle, the various machining sequences can be monitored in real time via one of two COLOUR TOUCHSCREEN 7 installed on the machine edge in the right-hand section. To make the straightening process more efficient, a INFRARED CERAMIC HEATER has been installed that heats the wheel without affecting the paint in any way. The AUTOMATIC TURNING, carried out in the left part of the machine, is guaranteed by a system QUICK CLAMP to fix the wheel on the axis of rotation, with absolute precision and stability; the movement of the CUTTING EDGE tool is carried out by two SERVOMOTORS, fitted on their respective zero-backlash ball guides, to ensure the movement of the tools with micrometric precision, for a long time and without any maintenance. The bright LED lamp IP67 provides a clear and precise view of the working area. A compressed air gun is available to easily remove aluminum chips, machining scrap. Both the STRAIGHTENING and TURNING operations can also be performed in MANUAL MODE, so that the operator can make corrections as he wishes. The compact and well-proportioned design makes the SPEEDYROUND CNC perfectly adaptable to the layout of any workshop. Contact us now for more information about the excellent performance of the Speedyround CNC. Choose with confidence all the quality and performance of this excellent product "Made in Italy"!

Straighten car wheels

TECHNICAL FEATURES

| Description | Dimensions |

|---|---|

| Working capacity | 10" - 28" |

| Maximum wheel width | 14" |

| Power supply | 220 Volt 1Ø – 50/60 Hz – 16Amp. |

| Sound level | 52 db |

| Dimensions (WxDxH): | 2000 x 800 x 1800 mm |

| Weight | 390 Kg. |